OTECO Fluid End Parts

OTECO offers a full line of quality fluid end pump parts for all popular mud pumps to suit any drilling condition. OTECO Fluid End Parts are manufactured to exacting standards that meet or exceed original equipment specifications and API standards.

Bonded Urethane and Premium Pistons

OTECO’s innovative bonded polyurethane piston dramatically extends service life in triplex mud pumps with ample water cooling. Harder, more dense polyurethane construction provides superior resistance to abrasive fluids providing optimum service life in harsh drilling conditions. In addition, the urethane construction is especially resistant to chemicals and oil based drilling muds with varying aniline points.

OTECO’s innovative bonded polyurethane piston dramatically extends service life in triplex mud pumps with ample water cooling. Harder, more dense polyurethane construction provides superior resistance to abrasive fluids providing optimum service life in harsh drilling conditions. In addition, the urethane construction is especially resistant to chemicals and oil based drilling muds with varying aniline points.

The multi-ply, fabric reinforced backing used in the production of the piston rubbers provide positive, wear resistant seals. High tensile strength, resistance to chemicals, hydrocarbons, and abrasion, long lasting service, and full interchangeability with other API designed pistons makes the OTECO Premium piston a sound value.

Wing Guided Valves and Full Open Seats

The OTECO premium wing guided valve and full open seat features greater fluid flow through the full open seat. The full open seat provides easier valve maintenance and seat pulling, in valve-over-valve fluid ends. Innovative unibody valve design eliminates snap rings, plates or keepers providing reduced maintenance by snap-on valve inserts. This combination will handle lost circulation material better than most conventional style valves and seats while the seating angle greatly improves flow characteristics and the heavy-duty load bearing capacity greatly improves service life.

The OTECO premium wing guided valve and full open seat features greater fluid flow through the full open seat. The full open seat provides easier valve maintenance and seat pulling, in valve-over-valve fluid ends. Innovative unibody valve design eliminates snap rings, plates or keepers providing reduced maintenance by snap-on valve inserts. This combination will handle lost circulation material better than most conventional style valves and seats while the seating angle greatly improves flow characteristics and the heavy-duty load bearing capacity greatly improves service life.

Premium Stem Guided Valves & Seats

The OTECO premium stem guided valve and seat features an extra wide metal to metal seal on the valve flange. The serrated upper surface on the valve gives a longer non-breathing seal between valve body and insert while the rigid seat cross-arms give greater strength and positive sealing. The strong, thick, valve knock off nut holds the insert tightly reducing flex and breathing which lessens the chance of foreign matter getting between valve and insert. The premium stem guided valve and seat provide good value, are economically priced, and weigh less than many competitors valve and seat.

The OTECO premium stem guided valve and seat features an extra wide metal to metal seal on the valve flange. The serrated upper surface on the valve gives a longer non-breathing seal between valve body and insert while the rigid seat cross-arms give greater strength and positive sealing. The strong, thick, valve knock off nut holds the insert tightly reducing flex and breathing which lessens the chance of foreign matter getting between valve and insert. The premium stem guided valve and seat provide good value, are economically priced, and weigh less than many competitors valve and seat.

OTECO Manifold Fittings

OTECO full flow high pressure fittings are manufactured from ASTM A-216 Grade WCB carbon steel castings. This assures excellent ductility and weldability.

- Screwed API line pipe fittings available in 2-, 3- and 4-inch sizes.

- OTECO 2-, 3- and 4- and 5-inch fittings available in buttweld end connections.

- OTECO fittings are hydrostatically tested in plant. Reduces chance for leaks in the field.

- OTECO manifold fittings are contoured and sized to minimize flow resistance and abrasive wear. Less chance of washout.

- Rated up to 5,000 psi (345 bars) working pressure standard.

- Special fittings and connections available on request.

Manifold Fittings Description Table

| Size | Description | Descriptive No. | Approx. Wt. Lbs |

| 2” | Long sweep full flow tee Long sweep tee 90° long sweep Ell 45° long sweep Ell Long sweep Y | 222-T 222-LST 22-L-90 22-L-45 222-Y | 51 60 30 12 51 |

| 3” | Long sweep full flow tee Long sweep tee 160° standpipe gooseneck with top outlet 90° long sweep Ell 45° long sweep Ell | 333-T 333-LST 333-GTO 333-L-90 33-L-45 | 97 80 105 67 20 |

| 4” | Long sweep full flow tee Long sweep tee 160° standpipe gooseneck 180° standpipe gooseneck 160° standpipe gooseneck with top outlet 90° long sweep Ell 45° long sweep Ell 90° long sweep Ell with 2” outlet Long sweep Y Full flow cross | 444-T 444-LST 44-G6 44-G8 444-GTO 44-L-90 44-L-45 424-L-90 444-Y 4444-X | 140 115 109 129 142 87 55 95 162 206 |

| 5” | Long sweep full flow tee Long sweep tee 160° standpipe gooseneck 180° standpipe gooseneck 160° standpipe gooseneck with top outlet 90° long sweep Ell 45° long sweep Ell 90° long sweep Ell with 2” outlet Full flow cross | 555-T 555-LST 55-G6 55-G8 555-GTO 55-L-90 55-L-45 525-L-90 5555-X | 200 161 200 220 220 116 74 140 515 |

Pressure Relief Valve (PRV)

Overview

The OTECO type PRV (shear type) Relief Valve helps ensure protection for slush pumps, manifolds, and other expensive components used in drilling operations. The PRV relief valve utilizes shear pins to relieve overpressure during drilling and other operations. Hardened stainless steel stems and stainless steel liner subs provide improved corrosion resistance resulting in higher reliability and longer valve life. With the OTECO PRV pressure relief valve, replacing shear pins is fast and easy because of the easy to remove safety cover. The OTECO PRV is available in 2 inch low, standard, and high pressure, as well as 3 inch high pressure models.

PRV Features and Benefits

- A metal chart is installed on every valve detailing shear pin selection specifications.

- Hardened stainless steel stems and liner subs provide corrosion resistance.

- PRV relief valve parts are interchangeable with Cameron style shear relief valve parts.

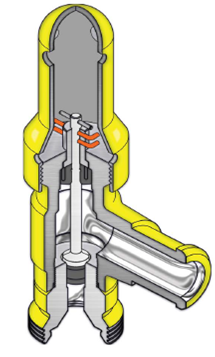

Manual Reset Relief Valve-Type RR

Overview

The type RR manual reset relief valve protects slush pumps and mud manifolds while guaranteeing greater safety in operation. The RR relief valve automatically snaps to a full open position when the predetermined pressure is exceeded or can be manually opened by simply pressing the manual release button. The position of the release button indicates at a glance whether the valve is open or closed. The RR is designed with a pressure setting indicator (available in metric units) which can be adjusted to any setting within the operating range by simply turning a nut on the top of the valve.

- RR Features and Benefits

- Release pressure setting is not affected by vibration during operation.

- Utilizes stainless steel piston and Cadmium-plated sub for improved corrosion resistance.

- Does not require shear pins.

- Fully enclosed bonnet assembly retains grease coating on moving parts extending service life.

- Bonnet assembly is interchangeable with Cameron Type ‘A’ and Type ‘B’ reset relief valves.

Pressure Relief Valve (PRV) 7,500 PSI

- OTECO P/N 133075

- 3″ Pressure Relief Valve

- Pressure Range 1,500 thru 7,500 psi

- Standard Service with 3″ Fig. 1502

- Female Inlet and 3″ Fig.

- 1502 Male Outlet Connections

- ( Estimated weight : 122 lbs )

BOP and Control Head Products

OTECO provides replacement packing units and seals for the Hydril ‘GK’ & ‘MSP’ and Regan type ‘K’ annular blow out preventors. These items are available in natural, neoprene, and nitrile rubber compounds with each unit tested to its full working pressure prior shipment. In addition, OTECO offers replacement rubbers for Shaffer type ‘39’, Guiberson types ‘A’ & ‘B’, and Cameron types ‘QRC’, ‘SS’, and ‘U’ ram type blow out preventors.

OTECO provides replacement packing units and seals for the Hydril ‘GK’ & ‘MSP’ and Regan type ‘K’ annular blow out preventors. These items are available in natural, neoprene, and nitrile rubber compounds with each unit tested to its full working pressure prior shipment. In addition, OTECO offers replacement rubbers for Shaffer type ‘39’, Guiberson types ‘A’ & ‘B’, and Cameron types ‘QRC’, ‘SS’, and ‘U’ ram type blow out preventors.Diaphragms & Bladders

OTECO supplies replacement diaphragms and parts for the Hydril and Mattco 10 and 20 gallon pulsation dampeners. These diaphragms are molded in one piece and are available in 1500 psi, 3000 psi, and 5000 psi ratings. They also have a metal insert molded into the bottom to prevent extrusion into the bottom flange connection. Stabilizers, plates, screws, lock washers, bottom plate gaskets, charging valves, and pressure gauges (0-6000 psi) are also available.

OTECO supplies replacement diaphragms and parts for the Hydril and Mattco 10 and 20 gallon pulsation dampeners. These diaphragms are molded in one piece and are available in 1500 psi, 3000 psi, and 5000 psi ratings. They also have a metal insert molded into the bottom to prevent extrusion into the bottom flange connection. Stabilizers, plates, screws, lock washers, bottom plate gaskets, charging valves, and pressure gauges (0-6000 psi) are also available.Pipe and Kelly Wipers

OTECO offers a wide range of pipe and Kelly wipers. These pipe wipers are offered in single, double, oval, and handle bar types and are available in either natural (black), or oil resistant (red) nitrile rubber compounds. In addition, the double wipers are available in solid, split, and split rap-a-round configurations. OTECO pipe wipers offer greater tearing resistance due to a reinforced insert molded to the resilient live rubber.

OTECO offers a wide range of pipe and Kelly wipers. These pipe wipers are offered in single, double, oval, and handle bar types and are available in either natural (black), or oil resistant (red) nitrile rubber compounds. In addition, the double wipers are available in solid, split, and split rap-a-round configurations. OTECO pipe wipers offer greater tearing resistance due to a reinforced insert molded to the resilient live rubber.OTECO Kelly wipers are molded from the same high quality rubber as the piper wipers and are offered for both square and hexagonal kellys. The Kelly wipers are reinforced with a bonded metal ring to provide longer service life for the wiper as well as the Kelly drive bushing.

Rotating BOP & Tubing Stripper Rubbers

OTECO manufactures a wide range of models and sizes of rotating BOP and tubing stripper rubbers. The current rotating BOP models offered include the interchangeable parts for the Shaffer Type 50, 74, 79, Lynn International, Shaffer 51, and the Grant 7068. Tubing stripper rubbers are offered for the following stripper heads:

OTECO manufactures a wide range of models and sizes of rotating BOP and tubing stripper rubbers. The current rotating BOP models offered include the interchangeable parts for the Shaffer Type 50, 74, 79, Lynn International, Shaffer 51, and the Grant 7068. Tubing stripper rubbers are offered for the following stripper heads:- Beaumont Iron Works PX-70 and PX-107

- Cameron Petromec PC & QD

- Guiberson Type J2 & JU

- Gulfco Type TT & S6

- Hillerman Kelley Type HK

- Hinderliter Type SS, 4-S, & 4-1

- Hydril Type RS

- Larkin Type K & SR

- Norris Hinderliter 4-1

- Oil center tool type J-1, JF-1, Type T-16

- Rector Type R and Type SS

OTECO Rotating BOP & Tubing Stripper Rubbers Details and Specifications» Downlo