<div class=”table-page”>

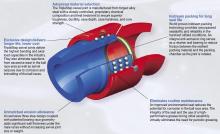

FMC Technologies Chiksan® TripleStep Swivel Joint

The TripleStep Swivel Joint designed to overcome the limitations of conventional swivel joints, the TripleStep swivel joint easily handles today’s severe fracturing fluids, radical temperature extremes, and high flow rates

Features and Benefits

- Flexibility in line layout similar to original Chiksan® swivel joints

- Patented TripleStep race design

- Thicker wall section under the male ball race minimizes erosion in this area

- “Stepped” ball race design lowers the stress in the ball race and creates stronger bearing race both in tensile and bending load applications

- Use of more balls to carry the load. More uniform ball load eliminates brinneling of ball race under hydrostatic test pressure.

- Less torque under pressure than competitive brands.

- Stronger & tougher material improves erosion resistant by 50%-200% due to the thicker wall section under the ball race of TripleStep design.

- Superior grease and environmental seals virtually eliminate swivel joint component scrapping due to ball race corrosion.

- Erosion is limited to elbow area not bearing race.

Chiksan® Swivel Joints are metal are metal pipe fittings with integral ball-bearing swivels. These rugged fittings come in 3/8- to 12-inch sizes and can handle cold working pressures up to 20,000 psi. Chiksan swivel joints are available for sour gas services at cold working pressures up to 15,000 psi. End connections are threaded, integral Weco® wing union, beveled for welding or flanged. Sour gas swivel joints have Weco wing union end connections.

Features and Benefits

- Pressure-tight seals protect bearings from line fluidChiksan swivel joints come standard equipped with nitrile packing and bonded, brass anti-extrusion ring.

- Bearings key to rotation, strengthTo assure long, dependable operation, Chiksan ball bearings are matched to loading and service conditions with two rows of bearings in each swivel and flame-hardened ball races.

- Smooth, round bore minimizes flow restrictionsChiksan swivel joints have smooth, round bores to minimize turbulence and keep pressure drop low.

- Simple maintenanceOnly occasional light greasing with a small, hand-held grease gun is required to keep Chiksan swivel joints on the job.

CHIKSAN® ORIGINAL SWIVEL JOINTS CATEGORIES:

175 psi (12 bar) to 1,000 psi (70 bar) cold working pressure;

3/4- to 12-inch sizes

Recommended service: Transfer lines, temporary flow lines, discharge lines, Auxiliary flow lines, water lines, and other general-service oilfield applications.

High-Pressure and Extra High-Pressure Swivel Joints

High-Pressure and Extra High-Pressure Swivel Joints

6,000 psi (414 bar) cold working pressure;

3/8- to 4-inch sizes

10,000 psi (690 bar) cold working pressure;

2-inch size

Recommended service:

Hydraulic control lines, mud lines, rotary line connections, BOP lines,

Test lines, water lines, offshore wellhead connections, cementing and circulating hoses, and choke and-kill lines.

7,500 psi (517 bar), 10,000 psi (690 bar), 15,000 psi (1034 bar), and 20,000 psi (1380 bar) cold working pressure;

1- to 4-inch sizes.

Recommended service:

Long-radius elbows designed especially for high-pressure sour gas abrasive applications such as fracturing, choke-and-kill lines, cementing and circulating hoses, acidizing, and test lines.

All Chiksan and Weco sour gas products meet or exceed NACE and API requirements. FMC began providing quality sour gas long before the National Association of Corrosion Engineers (NACE) Standard MR-01-75 was written. Today, all Chiksan and Weco brand products for sour gas service meet or exceed NACE Standard MR-01-75 and the American Petroleum Institute’s (API) Standard RP-14E.

Sour Gas Equipment Categories:

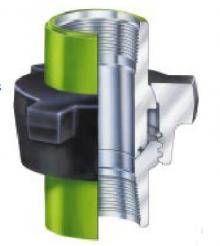

Weco® Wing Unions

Weco wing unions are the most complete line of sour gas pipe connections available, ranging in sizes from 2-to 6-inches with cold working pressure to 15,000 psi. All Weco unions are color coded with an olive green, zinc-chromatic primer for quick identification. Material meets NACE MR-01-75, ASTM and AISI standards.

Weco wing unions are the most complete line of sour gas pipe connections available, ranging in sizes from 2-to 6-inches with cold working pressure to 15,000 psi. All Weco unions are color coded with an olive green, zinc-chromatic primer for quick identification. Material meets NACE MR-01-75, ASTM and AISI standards.

Features and Benefits:

- Positive sealing designs, provide positive-pressure tight sealing

- Fast make-up and break-out

- End connections-butt weld connection and other end connections

Weco® Plug Valves

Weco sour gas plug valves are reliable, quarter-turn valves designed for services to 15,000 psi cold working pressure. These rigged valves range in size from 1 to 3 inches and come with integral Weco wing union ends. The union ends add considerable strength to connection, reduce turbulence, and minimize corrosion and stress concentration sites. Weco sour gas plug valves are available with manual, handwheel, and hydraulic actuators.

| Model DR Plug Valves |

|

| Model ULT Plug Valves |

|

Chiksan® Swivel Joints

Chiksan swivel joints are available in 2- to 4-inch sizes and can handle cold working pressure up to 15,000 psi in sour gas service.

Chiksan swivel joints are available in 2- to 4-inch sizes and can handle cold working pressure up to 15,000 psi in sour gas service.

Features and Benefits:

- Streamlined bore minimizes flow restrictions, minimizes turbulence and pressure drop

- Patented, Snap-in ball races, for extra strength and low operating torque

- Dual seal design isolates races and bearings, used to isolate the races and bearings from line fluid

- Leak detection port, between the primary packing and the secondary O-ring seal.

- Integral Weco wing union ends, eliminating welding and minimizing turbulence

- Field repairable

Weco® Pup Joints

FMC’s lightweight, one-piece pup joints feature integral Weco wing union end connections. Available in lengths to 10 feet, Weco alloy-steel pup joints efficiently handle sour gas fluids at cold working pressures up to 15,000 psi.

FMC’s lightweight, one-piece pup joints feature integral Weco wing union end connections. Available in lengths to 10 feet, Weco alloy-steel pup joints efficiently handle sour gas fluids at cold working pressures up to 15,000 psi.

Chiksan® Cementing & Circulating Hoses

Chiksan Cementing and Circulating Hoses can handle sour gas fluids at cold working pressures up to 15,000 psi. These rugged, all-steel hoses are available in sizes and configurations to meet all your sour gas needs. All materials meet NACE MR-01-75, ASTM or AISI standards.

| Features and Benefits: |

- Chiksan swivel joints-provide flexibility, absorb shock and vibration.

- Weco wing union connections-insure fast, pressure-tight make-up and break-out without threading, welding, or special connections.

| 4 Types of Chiksan® Cementing & Circulating Hoses: |

- LSG-10 Longsweep (2 Style 50 or Style 10) Intergral

- LSG-10 Longsweep (1 Style 50 and 1 Style 10) Intergral

- LSG-10 Longsweep (2 Style 50) Integral

- LSG-15 Longsweep (2 Style 50) Welded

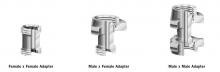

Weco® Adapters & Integral Fittings

Weco adapters and integral fittings are ideal for handling sour gas fluids at cold working pressures up to 15,000 psi. These proven products feature high-quality forged construction with integral Weco wing union end connections for a high-strength, high-integrity connection every time. Tees, elbows, crosses, wyes, and laterals can be combined to suit virtually any installation.

Weco adapters and integral fittings are ideal for handling sour gas fluids at cold working pressures up to 15,000 psi. These proven products feature high-quality forged construction with integral Weco wing union end connections for a high-strength, high-integrity connection every time. Tees, elbows, crosses, wyes, and laterals can be combined to suit virtually any installation.

Weco® Pressure Relief Valves

Weco Pressure Relief Valves for sour gas service are the automatic way to relieve pressure at preset system limits. These rugged, compact valves are available for cold working pressures up to 10,000 psi. The pressure relief valve comes in a 2-inch size with integral Weco wing union ends.

Weco Pressure Relief Valves for sour gas service are the automatic way to relieve pressure at preset system limits. These rugged, compact valves are available for cold working pressures up to 10,000 psi. The pressure relief valve comes in a 2-inch size with integral Weco wing union ends.

Weco® Swing Check Valves

FMC’s patented flowline check valves are used to isolate well servicing equipment from high pressure fluids. These rugged valves seal against sour gas fluids up to 10,000 psi. They are available with or without a downstream vent (consult factory), and are available with integral Weco wing union ends.

FMC’s patented flowline check valves are used to isolate well servicing equipment from high pressure fluids. These rugged valves seal against sour gas fluids up to 10,000 psi. They are available with or without a downstream vent (consult factory), and are available with integral Weco wing union ends.

Weco® butterfly valves offer the ultimate in dependable, economical flow control. These field-proven valves are available from stock in 2 through 24-inch sizes and can handle working pressures up to 175 psi. For pressure ratings from 176 psi up to 285 psi, consult factory. Wafer, notched, and lug-type body styles meet requirements for new or existing flowline systems. Using a variety of materials, valve bodies, discs, stems, and seats can be individually matched to specific operating conditions, including temperature range, type and concentration of fluid, and various flow conditions. All materials meet ASTM and AISI standards.

Weco® Butterfly Valve Features and Benefits

Standard Materials of Construction

| Valve Part | Standard Material | Optional Materials |

| Seat & O-ring | Nitrile (Buna N) (-20° F to 200°F) | Hypalon®, Teflon®, Viton®, EPDM, Red Natural Rubber |

| Body | Ductile Iron | Aluminum, Steel, Stainless Steel |

| Stem (upper & lower) | 410 Stainless Steel | 316 Stainless Steel |

| Disc | Ductile Iron | Aluminum Bronze, 316 Stainless Steel, Ryton®, Kynar®, Halar, Teflon® Coated, Nickel Plated, Hastelloy® |

| Spirol/Retainer Pins | 302 Stainless Steel |

WECO® BUTTERFLY VALVES CATEGORIES:

Short neck, wafer body; 175 psi cold working pressure, 2 to 12-inch sizes; 150 psi cold working pressure, 14 and

16-inch sizes

Recommended service:

General on/off and throttling services from 1mm Hg absolute vacuum to full working pressure

Features: Valves are self-centering and mount between 125 or 150 lb ANSI flanges

Short neck, notched body; 175 psi cold working pressure, 2 to 6-inch sizes

Recommended service:

General on/off and throttling services from 1mm Hg absolute vacuum to full working pressure

Features: Valves are notched to fit between lightweight flanges

Long neck, wafer body; 175 psi cold working pressure, 2 to 12-inch sizes

Recommended service:

General on/off and throttling services from 1mm Hg absolute vacuum to full working pressure

Features: Valves are self-centering and mount between 125 or 150 lb ANSI flanges, Long neck allows for pipe insulation

Long neck, lug body, 175 psi cold working pressure, 2 to 24-inch sizes

Recommended service:

General on/off and throttling services from 1mm Hg absolute vacuum to full working pressure

Features: Tapped lugs allow independent upstream or downstream bolting to 125 or 150 lb ANSI flanges, Long neck allows for pipe insulation

OPERATORS AND ACTUATORS:

Double-acting or fail-safe spring return; 2 through 12-inch valve sizes

Recommended service:

Pneumatic actuator for on/off valve operation

Features: Mounts directly to Weco butterfly valves without special adapters or mounting hardware, Full 90° operation with a minimum of 30 psi air, no adjustments required.

Quarter-turn, double acting actuator; 2 through 6-inch valve sizes

Recommended service:

Compact, pneumatic actuator for on/off valve operation

Features: The only moving part, the vane, is cast integral to the shaft for sturdiness; does not require field lubrication, fully repairable in-line, Mounts directly to valve in any quadrant.

Weatherproof, worm gear operator; 2 through 24-inch valve sizes

Recommended service:

Manual on/off or throttling services

Features: Operator has 90° travel arc with internal travel stop screws for a plus or minus 20° adjustment at either end of the travel, mounts on the valve in any quadrant, Chain wheel attachment available, and Hand-wheel shaft extensions available.

2 through 12-inch valve sizes

Recommended service:

Recommended for 8-inch valves and larger, manual on/off service

Features: Positive-stop gripper with integral locking lug ensures full open/full closed operation; Model 12 and 12N valves have a detent plate which bolts on the valve body in each of four quadrants; Model 22 and 22L valve have a pre-notched top flange with on/off detent positions.

2 through 12-inch valve sizes

Recommended service:

Recommended for 8-inch valves and larger, manual throttling service

Features: Notched detent plate and positive-stop gripper with integral locking lug ensures positive locking in any of 10 positions from full open or full closed operation, Detent plate bolts on the valve body in each of the four quadrants.

Weco® butterfly valves offer the ultimate in dependable, economical flow control. These field-proven valves are available from stock in 2 through 24-inch sizes and can handle working pressures up to 175 psi. For pressure ratings from 176 psi up to 285 psi, consult factory. Wafer, notched, and lug-type body styles meet requirements for new or existing flowline systems. Using a variety of materials, valve bodies, discs, stems, and seats can be individually matched to specific operating conditions, including temperature range, type and concentration of fluid, and various flow conditions. All materials meet ASTM and AISI standards.

Weco® Butterfly Valve Features and Benefits

Standard Materials of Construction

| Valve Part | Standard Material | Optional Materials |

| Seat & O-ring | Nitrile (Buna N) (-20° F to 200°F) | Hypalon®, Teflon®, Viton®, EPDM, Red Natural Rubber |

| Body | Ductile Iron | Aluminum, Steel, Stainless Steel |

| Stem (upper & lower) | 410 Stainless Steel | 316 Stainless Steel |

| Disc | Ductile Iron | Aluminum Bronze, 316 Stainless Steel, Ryton®, Kynar®, Halar, Teflon® Coated, Nickel Plated, Hastelloy® |

| Spirol/Retainer Pins | 302 Stainless Steel |

WECO® BUTTERFLY VALVES CATEGORIES:

Short neck, wafer body; 175 psi cold working pressure, 2 to 12-inch sizes; 150 psi cold working pressure, 14 and

16-inch sizes

Recommended service:

General on/off and throttling services from 1mm Hg absolute vacuum to full working pressure

Features: Valves are self-centering and mount between 125 or 150 lb ANSI flanges

Short neck, notched body; 175 psi cold working pressure, 2 to 6-inch sizes

Recommended service:

General on/off and throttling services from 1mm Hg absolute vacuum to full working pressure

Features: Valves are notched to fit between lightweight flanges

Long neck, wafer body; 175 psi cold working pressure, 2 to 12-inch sizes

Recommended service:

General on/off and throttling services from 1mm Hg absolute vacuum to full working pressure

Features: Valves are self-centering and mount between 125 or 150 lb ANSI flanges, Long neck allows for pipe insulation

Long neck, lug body, 175 psi cold working pressure, 2 to 24-inch sizes

Recommended service:

General on/off and throttling services from 1mm Hg absolute vacuum to full working pressure

Features: Tapped lugs allow independent upstream or downstream bolting to 125 or 150 lb ANSI flanges, Long neck allows for pipe insulation

OPERATORS AND ACTUATORS:

Double-acting or fail-safe spring return; 2 through 12-inch valve sizes

Recommended service:

Pneumatic actuator for on/off valve operation

Features: Mounts directly to Weco butterfly valves without special adapters or mounting hardware, Full 90° operation with a minimum of 30 psi air, no adjustments required.

Quarter-turn, double acting actuator; 2 through 6-inch valve sizes

Recommended service:

Compact, pneumatic actuator for on/off valve operation

Features: The only moving part, the vane, is cast integral to the shaft for sturdiness; does not require field lubrication, fully repairable in-line, Mounts directly to valve in any quadrant.

Weatherproof, worm gear operator; 2 through 24-inch valve sizes

Recommended service:

Manual on/off or throttling services

Features: Operator has 90° travel arc with internal travel stop screws for a plus or minus 20° adjustment at either end of the travel, mounts on the valve in any quadrant, Chain wheel attachment available, and Hand-wheel shaft extensions available.

2 through 12-inch valve sizes

Recommended service:

Recommended for 8-inch valves and larger, manual on/off service

Features: Positive-stop gripper with integral locking lug ensures full open/full closed operation; Model 12 and 12N valves have a detent plate which bolts on the valve body in each of four quadrants; Model 22 and 22L valve have a pre-notched top flange with on/off detent positions.

2 through 12-inch valve sizes

Recommended service:

Recommended for 8-inch valves and larger, manual throttling service

Features: Notched detent plate and positive-stop gripper with integral locking lug ensures positive locking in any of 10 positions from full open or full closed operation, Detent plate bolts on the valve body in each of the four quadrants.

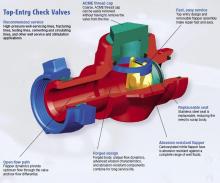

Weco check valves are used to isolate well-servicing equipment from high-pressure treating fluids during fracturing applications. Offered in three primary models, these rugged valves seal against a complete range of well-servicing fluids at pressures to 20,000 psi. Valves are available in 1-1/2 to 4-inch bore sizes for standard and reverse flow. Sour gas models available. Consult factory for configurations. Like all pressure containing products, Weco check valves require special handling.

Top-Entry Check Valves

High-pressure well-servicing lines, fracturing lines, testing lines, cementing and circulating lines, and other well service and stimulation applications

Dart Check Valves

Extreme nitrogen and carbon dioxide services; wet or dry non-erosive flow

Flapper Check Valves

Slick water, sand, proppant/gel, and cement services.

MC Technologies Weco® Integral Fittings and Pup Joints

Now there’s a new Lightweight Fittings family that is ideal for handling a complete range of well servicing fluids at cold working pressures to 20,000 psi. Available in 1- to 4-inch sizes, FMC fittings feature high-quality forged construction with integral Weco wing union end connections for a high-strength, high-integrity connection every time. Tees, elbows, crosses, wyes, and laterals can be combined to suit virtually any installation. Like other FMC flowline products, FMC’s Integral Fittings come with full material traceability and can be supplied with Charpy impact values.

Plug Valve Manifolds

FMC Integral Fittings can be used in combination with FMC Plug Valves to create manifolds for choke-and-kill, well testing, squeeze, flow back, and cementing applications. Unlimited manifold designs using FMC’s advanced ULT and world proven DR Plug Valves can be easily constructed. Because FMC’s new line of integral fittings are lighter and smaller, you save valuable weight and space regardless of manifold design.

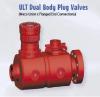

Weco ULT and DR plug valves are premium, quarter-turn valves designed for a wide range of standard and sour gas drilling, production, and well-servicing applications. These rugged valves are offered in single and dual-body designs in pressures to 20,000 psi. They range in size from 1 to 4-inches and come with threaded, Weco wing union, flanged, and clamp hub ends. Consult factory for configurations. Like all pressure containing products, Weco plug valves require special handling.

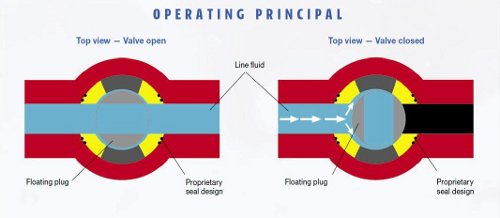

ULT Plug Valves-Benefits:

- Ultimate Seal-ability

The key to the ULT plug valve’s unprecedented seal integrity is its proprietary floating plug and dual-seal design. When the valve is closed, the dual segment seal provides a redundant seal on the downstream side of the valve.

- Ultimate Valve Body Life

When a ULT plug valve is closed, the only available flow path is between the seal segment and plug interface. This flow path eliminates body erosion and limits any potential wear to replaceable components.

- Ultimate Seal Life

The dual-seal design of the ULT plug valve, by forcing flow between the plug and segment interface, eliminates problem which is extrusion damage to the upstream and downstream segment seals.

- Ultimate Life Cycle Cost Savings

Superior sealability, increased life of valve body, and elimination of premature seal damage result in significant savings in life cycle costs of the ULT plug valve over traditional plug valves.

Operating Principal Plug Valve

WECO® PLUG VALVES:

ULT Plug Valves (3-inch and larger)

ULT Plug Valves (3-inch and larger)

Up to 20,000 psi cold working pressure

Recommended Service:

Slick water, sand, proppant/gel, and cement

SPECIALTY ULT PLUG VALVES:

ULT Flanged Plug Valves (Flanged End Connections)

ULT Flanged Plug Valves (Flanged End Connections)

Features and Benefits

- Widest selection in the oilfield

FMC offers the most complete line of standard service and sour gas wing unions with sizes ranging from 1- to 12-inches in diameter with working pressures up to 20,000 psi. Unions are available with line pipe or tubing threads, butt-weld, or nonpressure-thread seal end connections.

- Positive sealing designs

Weco wing union seals vary according to pressure and application. All wing unions provide positive, pressure-tight sealing.

- Fast make-up and break-out

Three-lug nuts and rugged self-locking ACME threads provide fast make-up and break-out regardless of position or space restrictions. No special tools are required.

- Simple Identification

Weco standard service wing unions are color coded for quick identification.

- Interchangeable parts

All Weco parts of the same size, pressure rating, and figure number are interchangeable.

- Rigid quality control

Weco unions are produced using the finest raw materials, tooling procedures, and heat-treating techniques available. Each union is carefully inspected to assure long, dependable service in the most extreme conditions.

Weco® Original Wing Unions

Figure 100

1,000 psi (69 bar) cold working pressure

1,000 psi (69 bar) cold working pressure

Recommended service: Manifold and line connections

Features: Pressure-tight make-up with hammer, economical low-pressure union

Figure 200

2,000 psi (138 bar) cold working pressure

2,000 psi (138 bar) cold working pressure

Recommended service: General-service manifolds and lines

Features: Economical, general-purpose union, 1- to 4-inch sizes, butt-weld available

Figure 206

2,000 psi (138 bar) cold working pressure

2,000 psi (138 bar) cold working pressure

Recommended service: Manifold and line connections, suction service, and corrosion service

Features: O-ring in male sub improves sealing and protects metal-to-metal seal against corrosion, replaceable O-ring extends union service life, 1- to 10-inch sizes

Figure 207

Blanking union, 2,000 psi (138 bar) cold working pressure

Blanking union, 2,000 psi (138 bar) cold working pressure

Recommended service: To seal manifold connections and protect union threads

Features: Parts are interchangeable with Figs. 200 and 206, O-ring on blanking cap ensures a leak-free seal, Raised lugs on cap allow for make-up with a hammer, Available in butt-weld, Cap can be tapped for pressure gauge if specified

Figure 211

Insulating union, 2,000 psi (138 bar) cold working pressure

Insulating union, 2,000 psi (138 bar) cold working pressure

Recommended service: For production systems with electrolytic corrosion problems

Features: Laminated insulating rings eliminate all metal-to-metal contact; insulating rings provide 35 million ohms resistance across the union, O-ring in male sub provides a positive primary seal, Seal ring in female sub provides a positive secondary seal, Insulating rings, O-ring, and seal ring can be replaced to extend union life

Figure 400

4,000 psi (276 bar) cold working pressure through 4-inch sizes;

4,000 psi (276 bar) cold working pressure through 4-inch sizes;

2,500 psi (172 bar) cold working pressure, 5- through 12-inch sizes

Recommended service: Manifold and line connections, pump suction, and mud service

Features: 2 1/2- through 12-inch sizes have O-rings for primary seal, Butt-weld available, Available for sour gas service: 2,500 psi (172 bar) cold working pressure, 5- through 12-inch sizes; 4,000 psi (276 bar) cold working pressure, 1- through 4-inch sizes

Figure 600

6,000 psi (414 bar) cold working pressure

6,000 psi (414 bar) cold working pressure

Recommended service: Steam service, boiler connections, manifold, and line connections for production, drilling and well servicing

Features: Bronze seat provides primary seal; will not rust in water services

Figure 602

6,000 psi (414 bar) cold working pressure

6,000 psi (414 bar) cold working pressure

Recommended service: Manifold and line connections and mud service

Features: Compact, Replaceable, lip-type seal provides primary seal, protects secondary metal-to-metal seal, and minimizes flow turbulence, Butt-weld available, Available for sour gas service: 6,000 psi (414 bar) cold working pressure

Figure 1002

10,000 psi (690 bar) cold working pressure through 4-inch sizes;

10,000 psi (690 bar) cold working pressure through 4-inch sizes;

7,500 psi (517 bar) cold working pressure, 5- and 6-inch sizes

Recommended service: Cementing, fracturing, acidizing, testing, and choke-and-kill lines

Feature: Replaceable, lip-type seal provides primary seal, protects secondary metal-to-metal, and minimizes flow turbulence, Butt-weld available, Available for sour gas service: 7,500 psi (517 bar) cold working pressure, 5- and 6-inch sizes have O-rings for primary seals

Figure 1003

Misaligning union, 10,000 psi (690 bar) cold working pressure, 2- and 3-inch sizes;

Misaligning union, 10,000 psi (690 bar) cold working pressure, 2- and 3-inch sizes;

7,500 psi (517 bar) cold working pressure, 4- and 5-inch sizes

Recommend service: For high-pressure connections where lines cannot be aligned

Features: Ball seat provides positive seal with up to 71/2° misalignment; 2-inch model up to 4°, Replacement O-ring on male sub provides primary seal, and protects metal-to-metal seal against abrasion and corrosion, Available with threaded or butt-weld ends

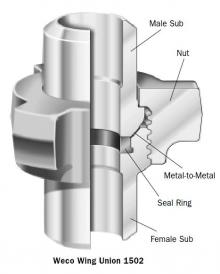

Figure 1502

15,000 psi (1034 bar) cold working pressure

15,000 psi (1034 bar) cold working pressure

Recommended service: Cementing, fracturing, acidizing, testing, and choke-and-kill lines

Features: Replaceable, lip-type seal provides primary seal, protects secondary metal-to-metal seal, and minimizes flow turbulence, Butt-weld available, Available for sour gas service: 10,000 psi (690 bar) cold working pressure; buttweld or nonpressure-thread seal configurations only

Figure 2002

20,000 psi (1380 bar) cold working pressure

20,000 psi (1380 bar) cold working pressure

Recommended service: Cementing, fracturing, acidizing, testing, and choke-and-kill lines

Features: Replaceable, lip-type seal provides primary seal, protects secondary metal-to-metal seal, and minimizes flow turbulence, 2- and 3-inch line sizes, Butt-weld configurations only

Figure 2202

15,000 psi (1034 bar) cold working pressure

15,000 psi (1034 bar) cold working pressure

Recommended service: Especially designed for sour gas service

Features: Meets National Association of Corrosion Engineers Standard MR-01-75 and American Petroleum Institute RP-14E, Heat-treated components are 100% tested for hardness, Fluoroelastomer seal rings, Butt-weld only, Stamped “sour gas” using low-stress dot stamping and painted with a green zinc-chromate primer to assure quick identification

</div>